1. What Role Do Solar Cables and Wires Play in Photovoltaic Power Generation?

Solar cables and wires are integral for photovoltaic power generation, serving as the crucial connectors between solar panels and other electrical equipment, enabling the transfer of electrical energy when necessary.

2. How Are Solar Panels Typically Mounted for Optimal Energy Conversion?

Solar panels are usually mounted on roofs or elevated structures to avoid obstructions, converting solar energy into usable electricity, which is then transmitted to the electrical unit by solar wires and cables.

3. Why Is Proper Installation of Solar Cables and Wires Crucial for PV Systems?

A well-planned and correctly installed network of solar cables and wires is essential for ensuring the safe and optimal functioning of PV systems, with photovoltaic wiring design requiring the proper use of solar cables and wires.

4. How Do Solar Wires and Solar Cables Differ?

While the terms solar wire and solar cable are often used interchangeably, they are different. A solar wire is a single conductor, whereas a solar cable is a composite of several conductors or wires held together by a jacket.

5. What Types of Solar Wires Are Used in PV Systems?

Various solar wires are used to connect PV system components, combining elements like solar panels, inverters, charge controllers, and batteries.

How Crucial Is Choosing the Correct Type of Wire for the Operation and Efficiency of a Photovoltaic System?

Selecting the appropriate wire in a photovoltaic system is pivotal to its functionality and efficacy. Utilizing an incorrect solar cord might result in inadequate voltage and power provision to the electrical unit or lead to the battery pack not being fully charged.

solar wire

1. What Are the General Compositions of Solar Panel Wires?

Typically, solar panel wires are either solid or stranded. A solid wire has a single metal core, while a stranded wire is composed of multiple stranded conductors.

2. How Does the Protective Sleeve Function in Solar Wires?

The protective sleeve insulates individual wires, but bare wires are also prevalent. Solid wire styles, recommended for static applications like household wires, have a more compact diameter for the same load-carrying capacity and are cost-effective for small gauges.

3. Why Might One Opt for Stranded Solar Wires?

Stranded solar wires, consisting of several conductors twisted together and jacketed, are more flexible and resilient to frequent movement. They are the standard choice for installations in locations with high winds or periodic vibrations due to their enhanced conductivity and are typically selected for large outdoor installations, despite having a larger diameter and higher cost compared to solid wires.

Wire composition

1. How Can Solar Wires Be Classified Based on Conductor Material?

Solar wires can be categorized according to the conductor material used, with aluminum and copper being the prevalent choices for domestic and commercial installations.

2. Why is Copper Wire Preferred for its Electrical Conductivity in Solar Installations?

Copper wire, compared to aluminum, exhibits superior electrical conductivity, allowing copper solar wires of the same size to carry more current than their aluminum counterparts. It offers flexibility, better heat resistance, and is suitable for both indoor and outdoor applications, albeit at a higher cost.

3. What Are the Characteristics and Applications of Aluminum Solar Wires?

Aluminum wire, being more affordable, is more rigid and prone to fragility when bent. It is available in larger sizes and is typically employed for outdoor installations like service entrances due to its cost-effectiveness.

wire

1. How Does Insulation Vary in Solar Wires, and What is its Purpose?

Insulation in solar wires, provided by the jacket, varies and is crucial for protecting the cable from elements like moisture, heat, chemicals, water, and UV rays.

2. Which Types of Insulation are Suitable for Different Conditions and Applications?

- THHN is apt for applications in dry, indoor conditions.

- TW, THW, and THWN are ideal for conduit applications in wet, indoor, or outdoor conditions.

- UF and USE (Underground Service Entrance) are designed for wet underground wiring, extending beyond just underground applications.

- THWN-2 is economical for indoor applications and can run directly to the primary service panel, adaptable for both DC and AC circuits with size variations post inverter.

- RHW-2, PV Wire, and USE-2 solar cables are optimal for wet outdoor applications, offering connections for solar panels, service terminal connections, and underground service entrances, with resilience to extreme UV exposure and moisture.

3. How Do PV Wire and USE-2 Solar Cables Stand Out in Outdoor Applications?

PV Wire and USE-2 solar cables are distinguished for outdoor applications due to their sheaths’ ability to withstand extreme UV exposure and moisture, with PV wires having additional insulation.

wire insulation

1. Why is Color-Coding Important in Solar Wires?

Color-coded solar wires facilitate the execution and illustration of electrical wiring plans, with wire colors denoting their purpose and function in the solar system, essential for future troubleshooting and repairs, as specified by the National Electrical Code.

2. How are Wire Colors Coded for Different Applications and Currents?

- For communication applications and ungrounded thermal applications, red, black, or other colors are used.

- White is utilized as a ground conductor.

- Green or bare wires are designated for equipment grounding.

- In DC applications, red is positive, and white is the negative or ground conductor.

3. What Should be Considered When Installing Electrical Systems with Color-Coded Wires?

When installing electrical systems, adherence to the National Electrical Code (NEC) recommendations is crucial. Additionally, consulting a certified electrician is advisable if there is uncertainty regarding the appropriate conductor and insulating material for a specific application.

wire color

1. How Are PV Wires Rated and Why is it Important to Choose the Correct Rating?

PV wires are rated based on their maximum current capacity, and choosing the correct rating is crucial to avoid voltage drop, overheating, and increased fire risk, especially for solar panels with higher amperage.

2. How Does Wire Thickness Relate to Its Amperage, and How Can One Determine the Appropriate Thickness?

The thickness of a solar wire is usually related to its amperage, with thicker wires having higher amplifier capacity. Using an American Wire Gauge (AWG) ruler and online wire size estimators can guide in choosing wires that are thick enough to handle the highest current in the system.

3. Why is Considering Wire Length Essential in Solar Installations?

The length of the solar wire impacts the amps it consumes, with longer distances requiring thicker wires for added safety to avoid risks associated with lower-rated wires.

4. What are the Recommendations for Choosing Wire Size and Length in Solar Installations?

Electricians recommend using thicker wires and considering future load requirements for the initial installation of solar cables, with specific wire sizes required for different installation lengths and maximum currents.

Wire Grade and Thickness

How Are PV Wires Rated, and Why is Thickness Important?

PV wires are crucial components in solar installations, rated based on their maximum current capacity. When dealing with solar panels with higher amperage (current), it’s essential to choose thicker solar wires with higher ratings.

Why is Checking the Amperage Rating Essential?

It’s vital to check the amperage rating of your system and select wires that can adequately handle the load. For instance, if your system produces nine amps, opting for a wire rated for 9 amps or higher (10 or 11 amps) is prudent.

What are the Consequences of Choosing Lower-Rated Solar Wire?

Selecting a lower-rated solar wire can lead to a voltage drop, causing overheating over time and escalating the risk of fire.

How is the Thickness of Solar Wire Related to its Amperage?

The thickness of a solar wire is inherently related to its amperage, with thicker wires having a higher amplifier capacity. It’s a general rule to use wires that are sufficiently thick or slightly thicker to accommodate occasional power surges.

How to Determine the Appropriate Wire Size?

Identify the device with the highest current in your system and choose a wire that can handle this current. Utilize online wire size estimators and an American Wire Gauge (AWG) ruler to measure the size of your solar PV copper wire accurately.

How Does the AWG System Work?

In the AWG system, the cables get smaller as the number of AWGs increases. For example, a 2 AWG solar wire has a larger diameter than a 12 AWG wire. However, wire size is inversely proportional to the amperage capacity of the wire, meaning a 2 AWG solar cable can handle 95 amps, while a 12 AWG solar wire can only handle 20 amps.

Keywords:

- PV wires

- Maximum current capacity

- Solar panels

- Amperage

- Wire thickness

- Voltage drop

- Overheating

- Fire risk

- Amplifier capacity

- Power surges

- Wire size estimator

- American Wire Gauge (AWG)

- Solar PV copper wire

line length

How Does the Length of Solar Wire Impact Safety and Efficiency in Solar Installations?

When considering solar installations, the length of the solar wire is a pivotal factor, impacting both safety and efficiency. The longer the power has to travel, the higher the amps it consumes, necessitating the use of slightly thicker wire for added safety.

Why is Using a Slightly Thicker Wire Important?

Using a thicker wire is crucial, especially when the power travels a longer distance, to prevent the risk of voltage drops, overheating, and fire. For instance, for an installation running 5 meters with a maximum current of 10 amps and an acceptable cable loss of 3%, a 6mm solar cable suffices. However, for the same installation running 15 meters, a 25mm solar cable is required.

What are the Recommendations for Wire Thickness and Length?

Electricians recommend using thicker wires for the initial installation of solar cables and preparing for future load requirements to ensure safety and efficiency in the long run. It’s always prudent to consider potential future expansions or modifications when selecting the wire thickness and length.

solar cable

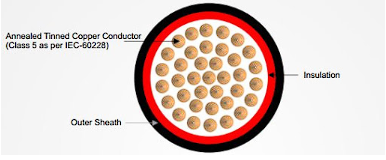

What Constitutes a Solar Cable, and How is it Utilized in Photovoltaic Systems?

A solar cable is a composite of several insulated wires enveloped by an outer sheath, primarily used by professionals to interconnect solar panels and other components in photovoltaic systems. These cables are designed to handle high UV radiation and temperatures and are weather-resistant, making them suitable for both internal and external installations on solar panels.

How is the Diameter of the Solar Cable Determined?

The diameter of the solar cable is contingent on the number of conductors it encompasses. Consequently, the classification of solar wires is predominantly based on the number and gauge of wires incorporated within.

What are the Different Types of Cables Used in Photovoltaic Systems?

In photovoltaic systems, generally, three types of cables are predominantly used: DC solar cables, solar DC main cables, and solar AC connection cables, each serving distinct purposes within the system.

DC Solar Cable

How are DC Solar Cables Configured and Utilized in Photovoltaic Systems?

DC solar cables, integral to photovoltaic systems, can be either modular cables or string cables. Typically, these cables are single-core, copper-based, equipped with insulation and jackets, and come with suitable connectors for seamless integration with photovoltaic solar panels.

What are the Characteristics of DC Solar Cables?

DC solar cables are pre-installed, meaning replacement is not an option. In certain configurations, a string to DC solar cable may be necessary to establish connections to other panels within the system.

Why are DC Solar Cables Important in Photovoltaic Systems?

DC solar cables are pivotal for interconnecting various components within photovoltaic systems, ensuring the efficient and secure transmission of solar energy from the panels to the subsequent elements in the system.

Main DC cable

How Do Main DC Cables Function in Solar Installations, and What are Their Typical Dimensions?

Main DC cables serve as larger collector cables in solar installations, connecting the positive and negative wires from the generator junction box to the central inverter. They come in typical dimensions such as Solar Cable 2mm, Solar Cable 4mm, and Solar Cable 6mm, and are a preferred choice for outdoor installations by experts.

What are the Considerations for Using Main DC Cables?

Using separate wires with opposite polarities is crucial when utilizing main DC cables to avoid short circuits and grounding problems, ensuring the reliability and safety of the solar installation.

What are the Variations in Main DC Cables?

Main DC cables can be either single-core or two-core cables. A single-core wire with double insulation is a practical solution for high reliability, while a two-core DC cable is typically chosen for wiring between the solar inverter and the generator junction box.

AC connection cable

How Does the AC Connecting Cable Integrate with Solar Systems, and Why is Choosing the Right Size Crucial?

The AC connecting cable plays a pivotal role in solar systems, interconnecting the solar inverter with protection equipment and the grid. It varies in structure depending on the type of solar system and its inverter.

How is the AC Connecting Cable Configured in Different Solar Systems?

For small solar systems utilizing three-phase inverters, a five-core AC cable is employed to establish a connection to the grid, comprising three live wires, one ground wire, and one natural wire. Conversely, single-phase photovoltaic inverter systems incorporate three-core AC cables.

Why is Correctly Sizing Cables Imperative in Photovoltaic Systems?

Choosing the right size cable is paramount to prevent overheating and minimize energy loss in photovoltaic systems. Beyond safety, using undersized cables is a breach of the National Electrical Code (NEC) in many jurisdictions, leading to installation rejections by building inspectors.

PV solar connector

PV solar connector