Solar Cable & Wiring Harness

1198YORO Solar: Offering High-Quality Solar Cables & MC4 Connectors with a 30-Year Warranty. Your Trusted Partner for All PV Plant Wiring and Installation Needs.

View detailsSearch the whole station

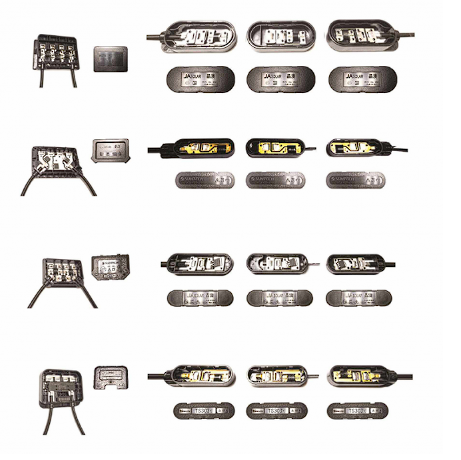

How To Choose The Model And Specification Of The Junction Box

In the realm of photovoltaic power generation systems, an inappropriate selection of a photovoltaic junction box can lead to the burning of solar panels or even the collapse of the entire photovoltaic system. As the adage goes, “Avoid sacrificing the greater for the lesser.” So, how should one approach the selection of a junction box to ensure optimal functionality and system integrity?

The junction box serves as a pivotal connector, forming a bridge between solar modules and control devices like inverters. It draws out the current generated by the solar module and introduces it to electrical equipment through the terminal block and connector, minimizing power loss with low-resistance conductive materials and ensuring minimal contact resistance of the bus strip’s lead wire.

The junction box’s protective functions are threefold. Firstly, it prevents the hot spot effect and safeguards the cells and components through bypass diodes. Secondly, it employs specialized materials to ensure waterproofing and fire resistance. Lastly, it utilizes a unique heat dissipation design to lower the working temperature of the junction box and the bypass diode, reducing power loss due to leakage current.

Weather resistance is crucial for materials exposed to the elements, ensuring they withstand climatic tests, including damage from light, temperature fluctuations, wind, rain, and bacteria. The junction box’s exterior components— the body, cover, and connector (PC)— are crafted from robust weather-resistant materials like PPO (polyphenylene ether), a top engineering plastic known for its high rigidity, heat resistance, flame retardancy, strength, and superior electrical properties. PPO’s minimal dielectric constant and loss, unaffected by temperature and humidity, make it suitable for varying electric fields, with a deformation temperature above 190℃ and an embrittlement temperature of -170℃.

Given the diverse and harsh working environments of components—ranging from tropical to high-altitude regions— the junction box must exhibit exceptional resistance to high and low temperatures, ensuring optimal performance in areas with significant daily temperature variations, like deserts.

Ultraviolet rays can significantly damage plastic products, especially in plateau areas where the air is thin, and ultraviolet irradiance is exceptionally high. A junction box with UV resistance is crucial in such regions to maintain the longevity and functionality of solar modules.

Flame retardancy is a crucial property, inherent or treated, that significantly delays the spread of flames. The flame retardant grade ascends from HB, V-2, V-1 to V-0, with HB being the lowest flame retardant rating in UL94 and CSA C22.2 No 0.17 standards. A higher grade ensures enhanced safety and durability of the junction box in varying environments.

Adherence to IEC62852 /UL6703 “Enclosure Protection Level (IP Code)” standards ensures the junction box’s resilience against water and dust, with an available level of IP65, safeguarding the components against environmental elements and prolonging operational life.

Heat within the junction box primarily arises from diode conduction and ambient temperature increases. Effective heat dissipation or specialized thermal designs are imperative to protect sealing rings and diodes from accelerated aging and to maintain the optimal power output of the components. While heat sinks are a common solution, their placement and integration need careful consideration to avoid adverse impacts on the junction box and its sealing integrity.

YORO Solar: Offering High-Quality Solar Cables & MC4 Connectors with a 30-Year Warranty. Your Trusted Partner for All PV Plant Wiring and Installation Needs.

View detailsYORO Solar: Unparalleled expertise in solar power systems and components. Offering high-quality photovoltaic wiring solutions with a 30-year warranty.

View detailsDelve into the maintenance of solar cables, focusing on daily checks, annual maintenance, post-operation inspections, and common faults. Learn the importance of regular upkeep, preventive tests, and addressing defects to ensure the longevity and r...

View detailsDelve into the evolution and pivotal role of solar connectors in enhancing the efficiency and reliability of solar power systems, focusing on advancements, environmental adaptability, and connection methods

View details